Why do we need water treatment in dialysis?

In dialysis, water is used for four different purposes:

- Mixing concentrate

- To make dialysate

- For dialyzer reprocessing

- To wash concentrate jugs

A normal human body can handle harmful substances in drinking water when healthy. The digestive system, immune system, and kidney help protect or get rid of those toxins. Patients who are on dialysis do not have that protection. On dialysis, blood comes in contact with dialysate through the dialyzer membrane. Contaminated water can cause illness or death. Therefore, water is passed through water treatment systems.

How does water become impure?

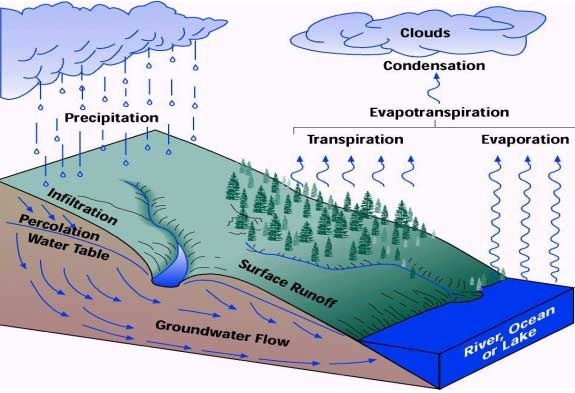

Water is the universal solvent. During rainfall, the water contacts air and reaches land and soil. From the air, it mixes with carbon dioxide (CO2), sulfur dioxide (SO2), and other pollutants. Once reached the land and soil, it further adsorbs contaminants such as calcium (Ca2+), magnesium (Mg2+), other elements and salts, industrial waste, and surfactants.

So, what are the types of impurities present in tap water?

There are several impurities in tap water, such as bacteria, viruses, pesticides, detergents, magnesium, calcium, hydrocarbons, chlorine, industrial waste, etc. These impurities depend on the source of water:

1. Groundwater

Groundwater is water from wells and springs. It contains many ions such as iron, calcium, and magnesium but relatively lower microbes than surface water.

2. Surface water

Surface water sources are generally lakes, ponds, rivers, and reservoirs. İt contains lower ions; however, higher pesticides, industrial waste, sewage, and microbes.

What are the toxic effects of some impurities?

Pure water quality produced is crucial for patient health. However, when the water quality is not of the required quality for dialysis, indications occur in dialysis patients due to the toxic substances in the water, which is quite dangerous.

|

Effect

|

Contaminants

|

|

Anemia

|

Aluminum, chloramine, copper

|

|

Hemolysis

|

Chloramine, fluoride

|

|

Bone disease

|

Aluminum, fluoride

|

|

Muscle weakness

|

Calcium, magnesium

|

|

Neurological changes

|

Aluminum, sodium, zinc

|

Some other indications are as follows:

- Encephalopathy

- Septicemia, pyrogenic reactions

- Chronic inflammation syndrome

- Complications of various elements

- β2-microglobulin amyloidosis

- Atherosclerosis

- Malnutrition

- Nanobacteria and vascular calcification

What are the methods used to treat water for hemodialysis?

Water is treated by using the combination of the below-mentioned units in hemodialysis:

- Filtration

- Adsorption

- Ion Exchange

- Reverse osmosis (RO)

- Ultraviolet (UV) disinfection

What are the components of a hemodialysis water treatment system?

- Particulate filtration

- Water tanks

- Booster pumps

- Backflow prevention

- Sediment filter

- Microfiltration

- Activated carbon filter

- Water softener

- Sampling valve and pressure control

- Reverse osmosis (RO)

- Deionization (DI)

- UV light

- Submicron filter

- Distribution system loop

Temperature and pH

The ideal temperature for reverse osmosis membranes is 25 °C. At lower temperatures, the RO membranes produce a lower volume of permeate water. However, at higher temperatures, the membranes could be damaged. The ideal pH for feed water in the hemodialysis water treatment system is 5.0-8.5. If the pH is higher than 8.5, a chemical dosing system may be used to inject a small amount of acid to lower the pH.

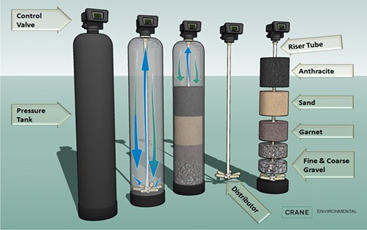

1. Sediment filter

The multimedia filter is the most common sediment filter and has layers of different-sized rocks. Due to these different-sized rocks, the filtration unit is also called a multimedia filter. It can remove particles bigger than 20 microns and sometimes as low as 10 microns. A sediment filter removes the particles in water that cause turbidity. These particles can clog activated carbon media and damage softener resin and RO membranes if not used. Multimedia filters are composed of multiple layers of media, typically coal (anthracite), sand (quartz), and garnet, which are of different sizes.

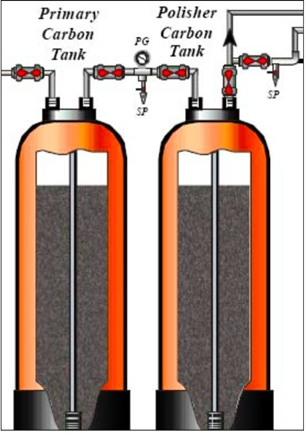

2. Carbon Filter

Activated carbon (GAC) is used in water treatment systems to remove chlorine and chloramine from water. These agents are commonly added to tap water in small quantities to prevent microbiological growth. However, if we fail to remove chlorine and chloramines from treated water, it can lead to severe hemolytic anemia in patients on dialysis. Also, free chlorine has been known to degrade certain reverse osmosis membranes, leading to holes in the membranes that causes failure of appropriate filtration.

Carbon filters also remove organic matter, odor-producing materials, pesticides, and industrial solvents by adsorption. Adsorption is the process in which liquids, gases, or suspended materials cling to a surface. Depending on the inlet water quality, one or two carbon tanks could be in the system. In case two tanks are installed in series, the first tank is named worker and the second as the polisher or backup. Using two tanks in series results in very effective removal of chlorine in the feed water and guarantees the treatment for failure cases in one of the carbon tanks.

Empty Bed Contact Time (EBCT)

EBCT is the time it takes for water to flow through the carbon tanks. According to AAMI, an EBCT of 10 minutes is effective in activated carbon tanks.

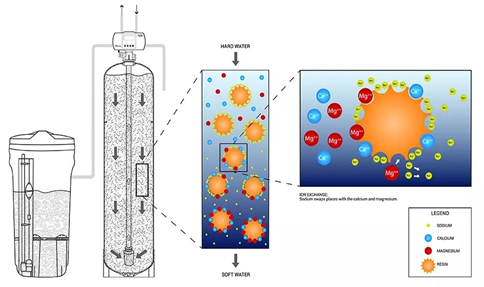

3. Water softener

A water softener is used to remove the hardness of the water. The hardness of water is due to the presence of calcium (Ca2+) and magnesium (Mg2+). These elements cause hardness in water in their carbonate, sulfate, or phosphate forms. Hard water syndrome is a dialysis-induced illness caused by using hard water to prepare dialysate that could result in nausea and vomiting during dialysis, extreme weakness, and unexpected changes in blood pressure.

A water softener removes hardness from water by a mechanism named ion exchange. The resin used inside the softener tanks can exchange the ions until the saturation point at which it becomes unable to exchange ions any further. At this point, regeneration with salt (brine), mainly sodium chloride (NaCl), is required to free the surface of the resin, activate it again, and prepare for hardness removal.

4. Microfiltration

Microfiltration is used to retain any particulates or media from the pre-treatment tanks to avoid mixing with other media and damaging electronic valves and other units. Different micron sensitivity, such as 20, 5, and 1 micron, are used between the pre-treatment units.

5. Reverse osmosis (RO)

It is the purification system itself that removes the organic and inorganic materials, minerals, bacteria, and endotoxins from water. In reverse osmosis, the molecules move from a concentrated solution to a less concentrated solution, pure water. For this process to occur, a pressure higher than osmotic pressure and a semipermeable membrane limiting the passage of dissolved ionic substances are needed. Pure water can be obtained thanks to the appropriate pressure and membrane. Reverse osmosis technology is the most sensitive membrane filtration technology known where up to 99.5% stable and 99.3% minimum salt removal occurs.

RIVAMED RO systems are generally able to treat up to 2000 ppm total dissolved solids (TDS) in water to pure water. However, when well water is used for dialysis, and if the water quality is not good enough that a standard system could treat it efficiently, then a second RO system is installed in a series called double-pass reverse osmosis or twin-pass reverse osmosis. Ultrapure water can be achieved using a double-pass RO system, and quality water can be provided for dialysis.

https://www.rivamed.com.tr/en-us/medical-treatment/hemodialysis-water-treatment-systems

6. Deionization (DI)

DI units are resin media where the ions remaining after RO are adsorbed to provide 0 µS/cm conductivity. These units are generally used as backup and only used when the RO is not functioning properly or needs extra purification.

7. Distribution Loop and Submicron Filtration

The distribution loop is the pipes and fittings that distribute the pure water to the dialysis machines and return. The loop is preferred as PE-Xa, where chances of contamination are minimal by the material of the pipes as well as a proper installation that leaves no dead legs. The loop contains stainless steel sampling valves, one on the outgoing line and one on the return.

Submicron filters used in hemodialysis water treatment systems loop is 0.22 mm pore diameter. They can be used for extra safety in the loop. When an ultraviolet disinfection unit is added after RO in the system, using an endotoxin filter, a submicron filter, is also a must to retain the endotoxin released from bacteria cell death.

What is the difference between a direct feed system and a system with a permeate tank?

In direct feed systems, RO is connected to the pure water loop and feeds the hemodialysis machines directly. RO boosts the purified water to the dialysis room and then returns to the RO.

In systems with a permeate water tank, pure water after RO or after the loop is stored in stainless steel or polyethylene permeate tank. Then, a booster unit, ultraviolet disinfection, and endotoxin filtration units are installed to boost the pure water to the loop and feed dialysis machines. These systems are preferred when the loop is very long or there is a water shortage.

Riva Engineering Water Treatment Systems have worked for more than 20 years in the hemodialysis water treatment sector and exported systems to up to 52 countries. We know the A-Z of the dialysis water treatment systems and provide turn-key solutions for your specific need. We provide the best quality dialysis water complying with AMMI, ANSI, and ISO standards and we hold the CE certificate according to Medical Devices Directive (MDD) 93/42/EEC for our systems. If you want to know more about our systems and are looking for a solution for your project, please do not hesitate to contact us.

RIVAMED, Save Water, Save Life!

www.rivamed.com.tr/en-us/contact/